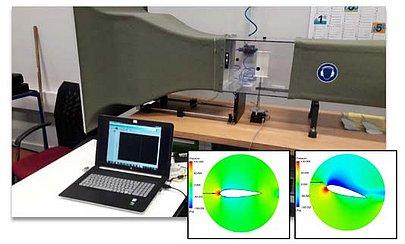

To investigate turbulent flow processes, either complex mathematical methods(computational fluid dynamics, CFD) are used or elaborate measurements are carried out. As a result, the lift and drag forces of the profiles of wings, for example, can be described as a function of the angle of attack as well as the turbulence behind the rotor. A small wind tunnel is available in the wind laboratory at htw saar for such investigations.

Figure 1: Small wind tunnel for measuring blade profiles for comparison with CFD results.

The phenomenon of stall can be represented in the simulation from certain angles of attack. Proof of such a stall can also be easily demonstrated in experiments by measuring the force. Three methods are available to provide visual evidence of these events. The first is schlieren photography(schlieren imaging), the third is a digital image processing technique(background oriented schlieren imaging, BOS) and the third is flow visualization using a smoke plume.

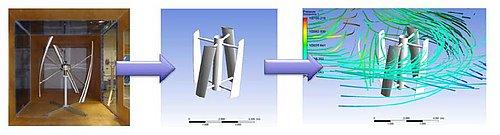

Figure 2: The entire innovation process is carried out, from design and simulation through to experimental investigations

Once the wing profiles have been designed, prototypes can be built and measured. Additivemanufacturing(AM) processes play a key role in producing the required free-form surfaces.

These prototypes are then tested in a large wind tunnel.

Students are closely involved in all steps of the innovation process. This is to be actively encouraged by setting up an open workspace directly in the wind laboratory.

Fluidenergiemaschinen