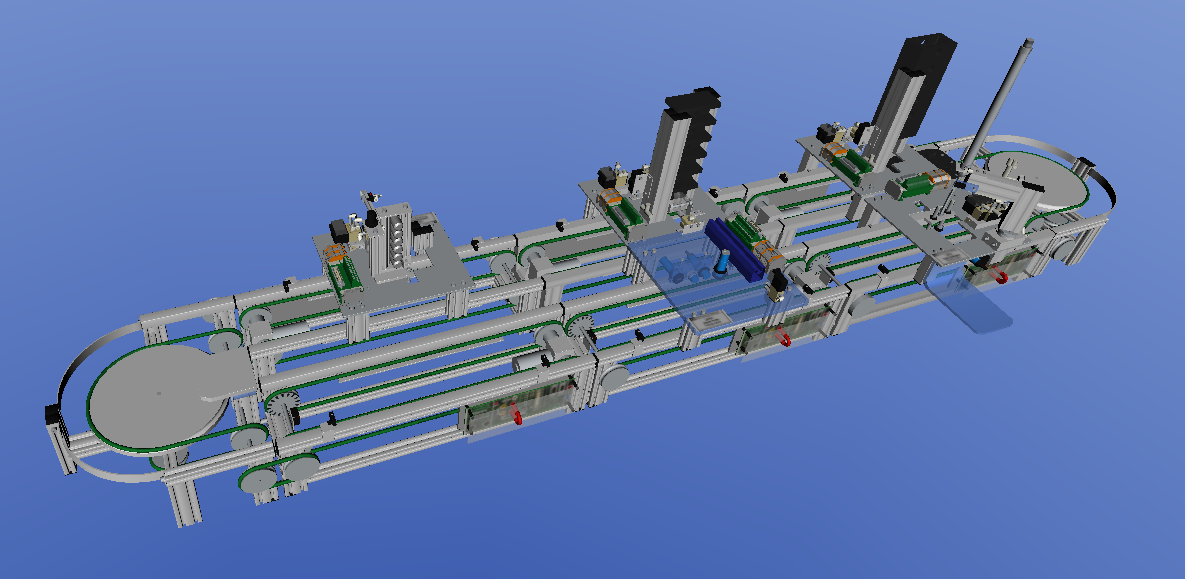

A digital twin is a virtual model that precisely mirrors a physical object. The Industry 4.0 learning environment - is equipped with various sensors that are logically linked by programmed function blocks. Programming the entire system is complex and difficult for beginners to understand.

With the help of the digital twin of the Industry 4.0 learning environment, beginners, advanced users and experts can reprogram or modify the function blocks without jeopardizing the existing programming of the physical Industry 4.0 learning environment.

The programming of the function blocks is transferred to the digital twin and shows the programmed function sequence. If the function sequence is as desired and does not show any errors, the programming can be transferred to the physical Industry 4.0 learning environment.

The digital twin allows programming to be tested without risk. The digital twin can also be used as a learning tool for learning programming skills in Siemens S7. To this end, the digital twin can be expanded or minimized as required and adapted to the user's level of experience.

Assisted learning is becoming increasingly important in modern production. It enables targeted and practical support for employees directly at the workplace, which shortens training times, reduces errors and ensures quality. Particularly in times of increasing complexity and flexible production processes, assisted learning makes a significant contribution to the efficiency and competitiveness of companies.

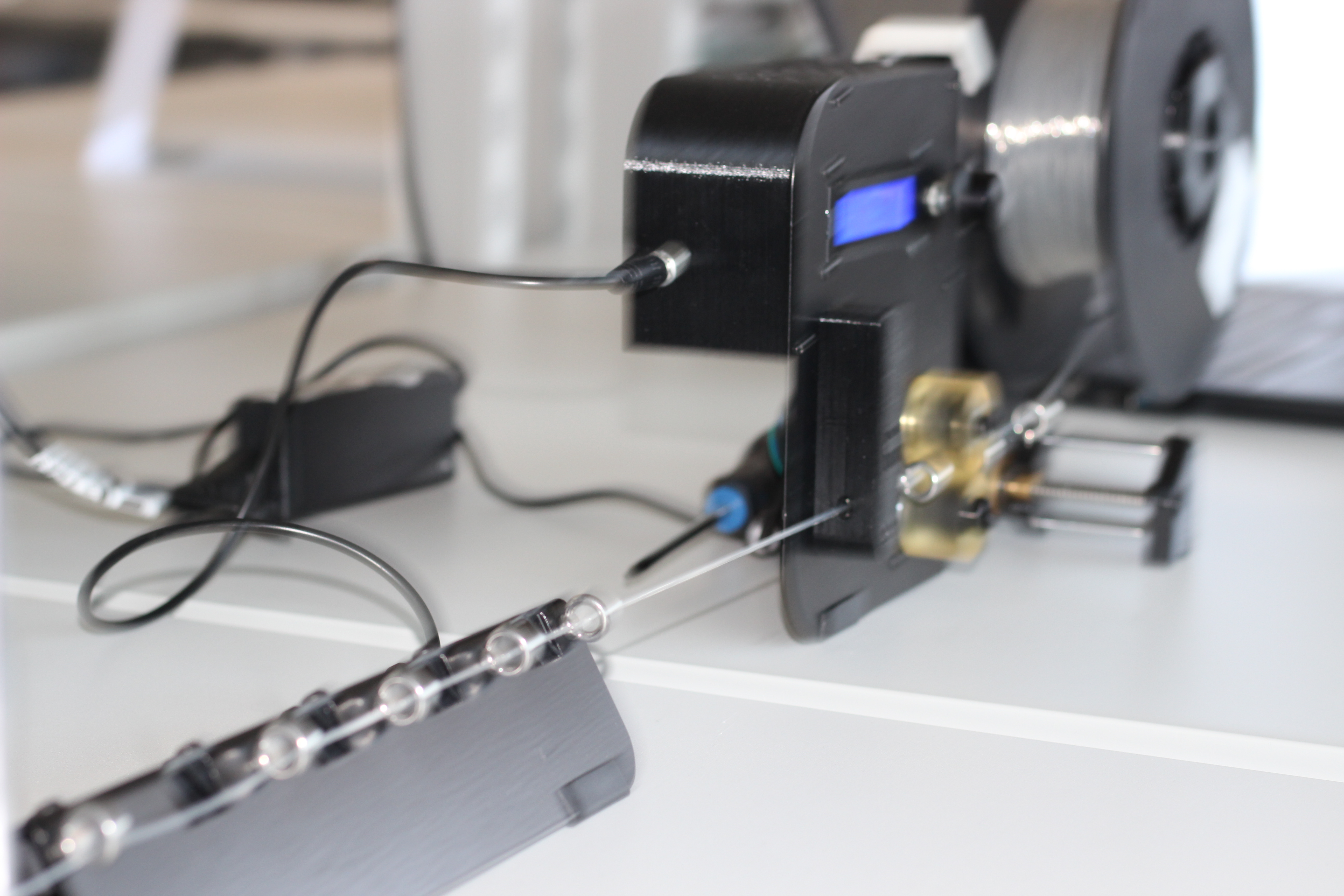

Assisted learning of measuring processes is made possible by means of a worker assistance system (Knowledge Guide) and the compatible measuring gauges. The technologies mentioned assist the user in the learning process of measuring. This is implemented at a manual workstation through guided instruction and use of the measuring equipment, the presentation of various measurement problems (e.g. between threads of screws) and continuous feedback from the worker assistance system. The learning process can be carried out in 3 different levels of difficulty.

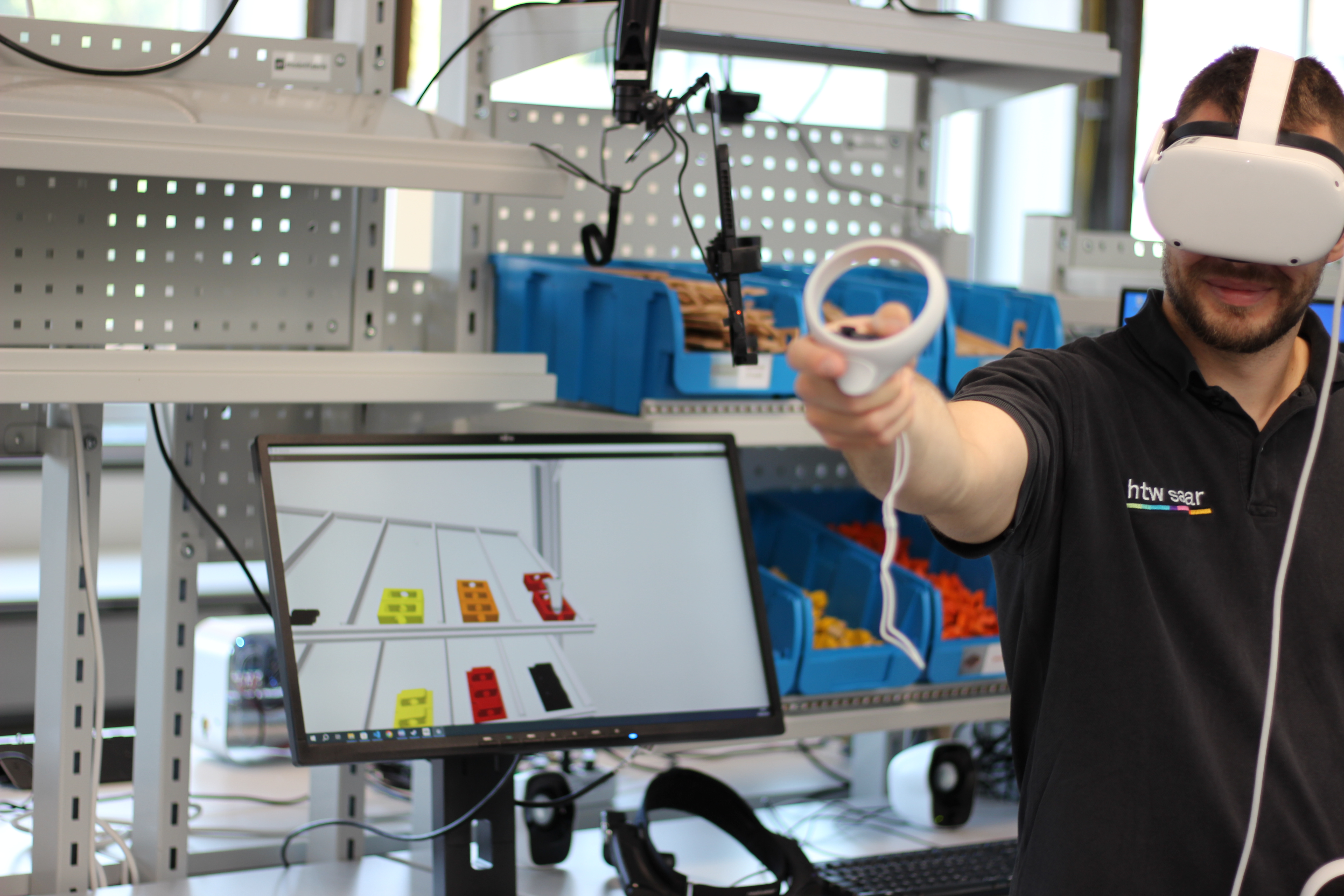

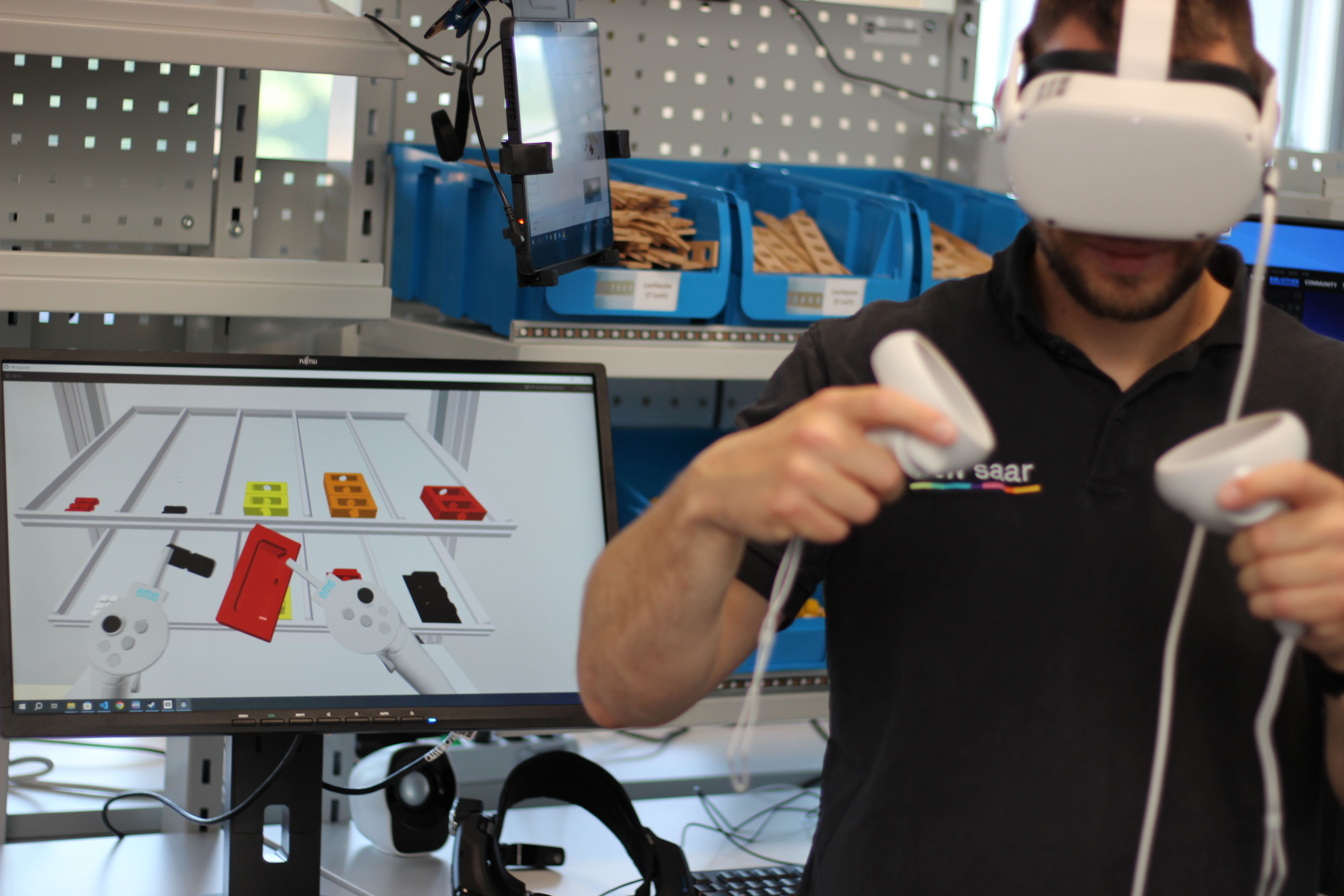

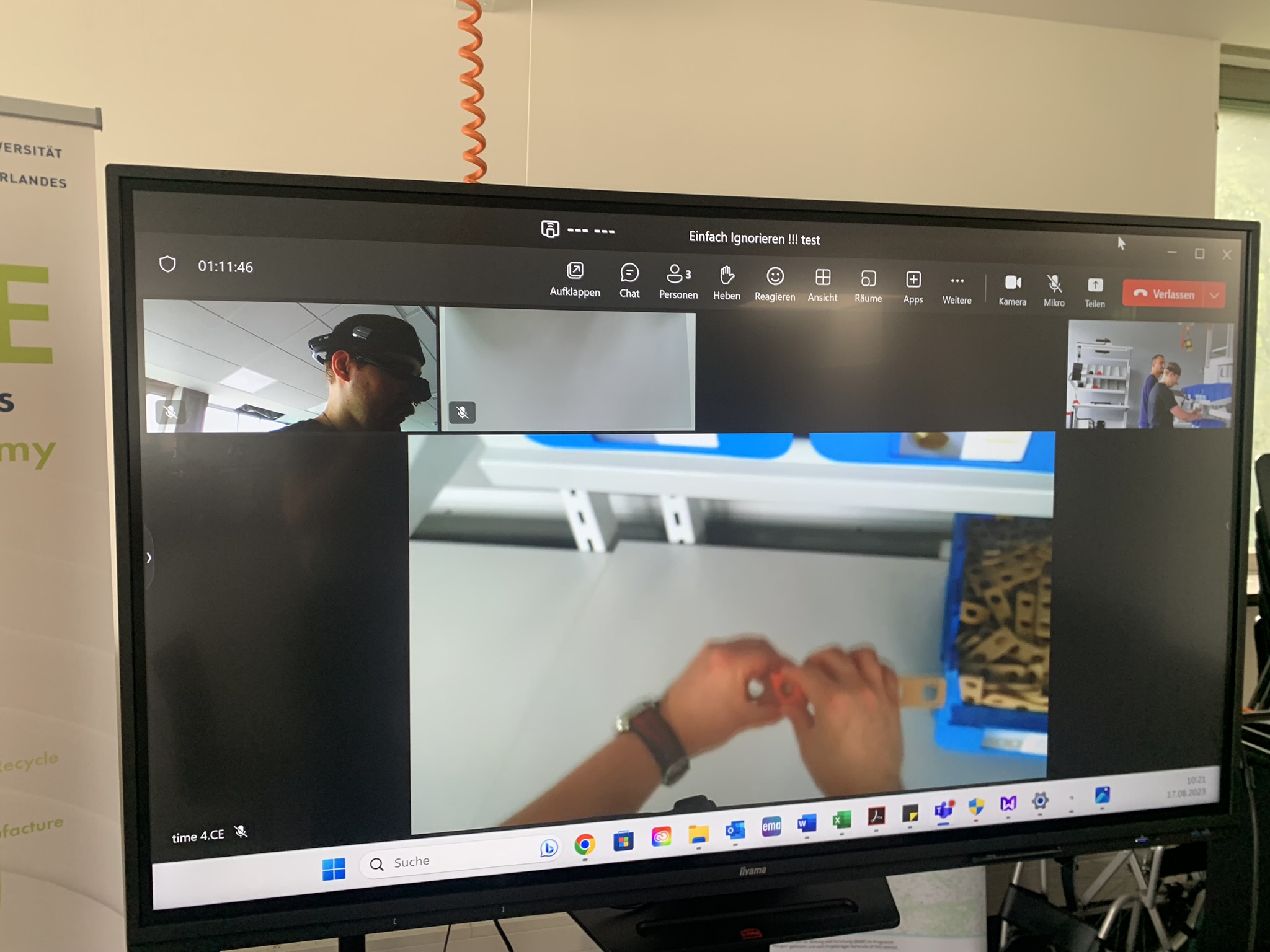

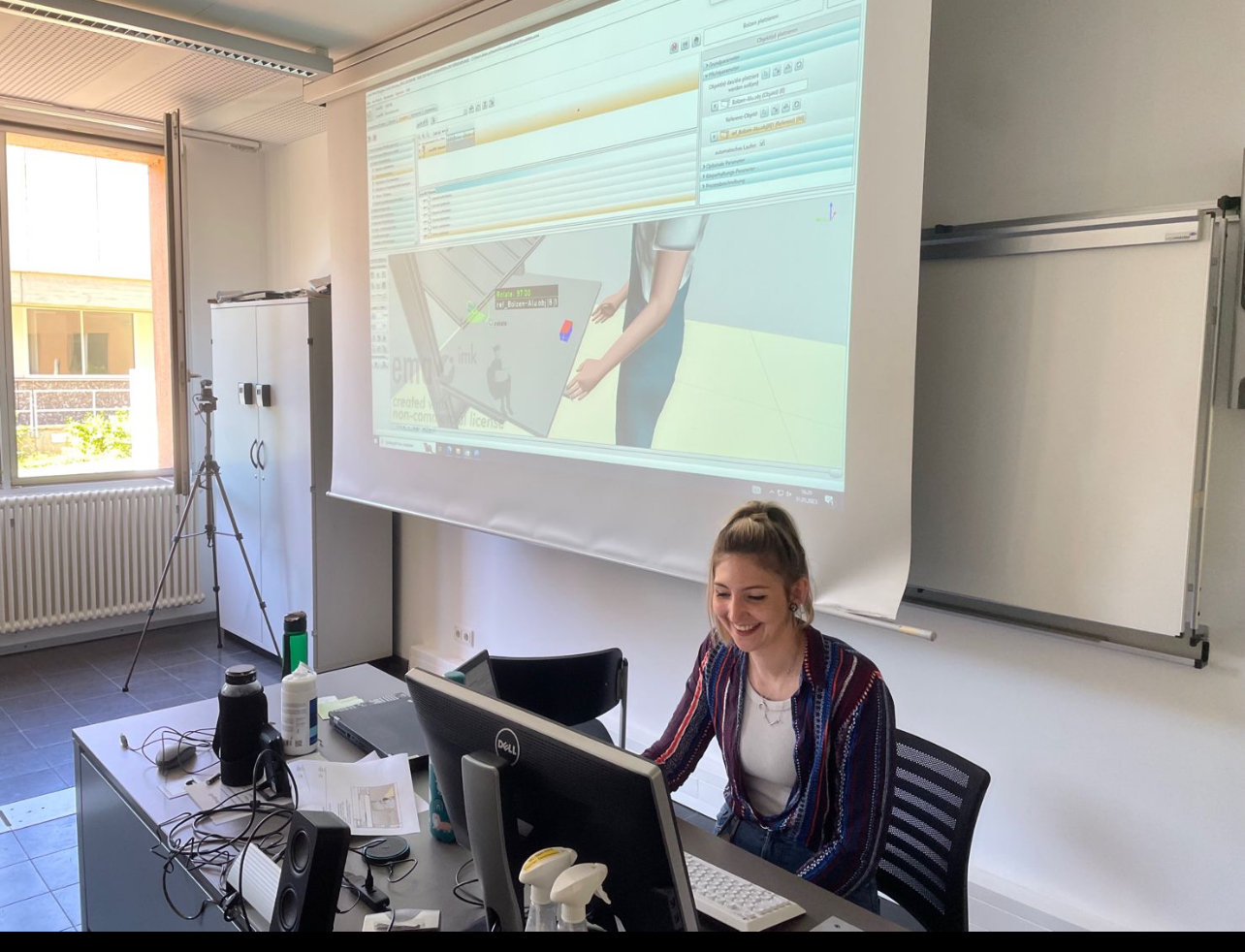

Simulations often look impressive and are perceived as a credible representation of reality. However, not everything that works in a computer simulation proves to be practicable or correct in reality. In order to illustrate this discrepancy between the virtual and real world and to sensitize the students to it, a (simple) individual workstation-related assembly including the worker is planned and the simulation model is tested.

The planning is divided into three phases: creating the work environment, defining the characteristics of the human model and defining work processes; the work environment should be a digital representation of the manual workstation from the WI model factory. The planning is then checked in reality in the model factory. This reveals discrepancies between planning and execution.

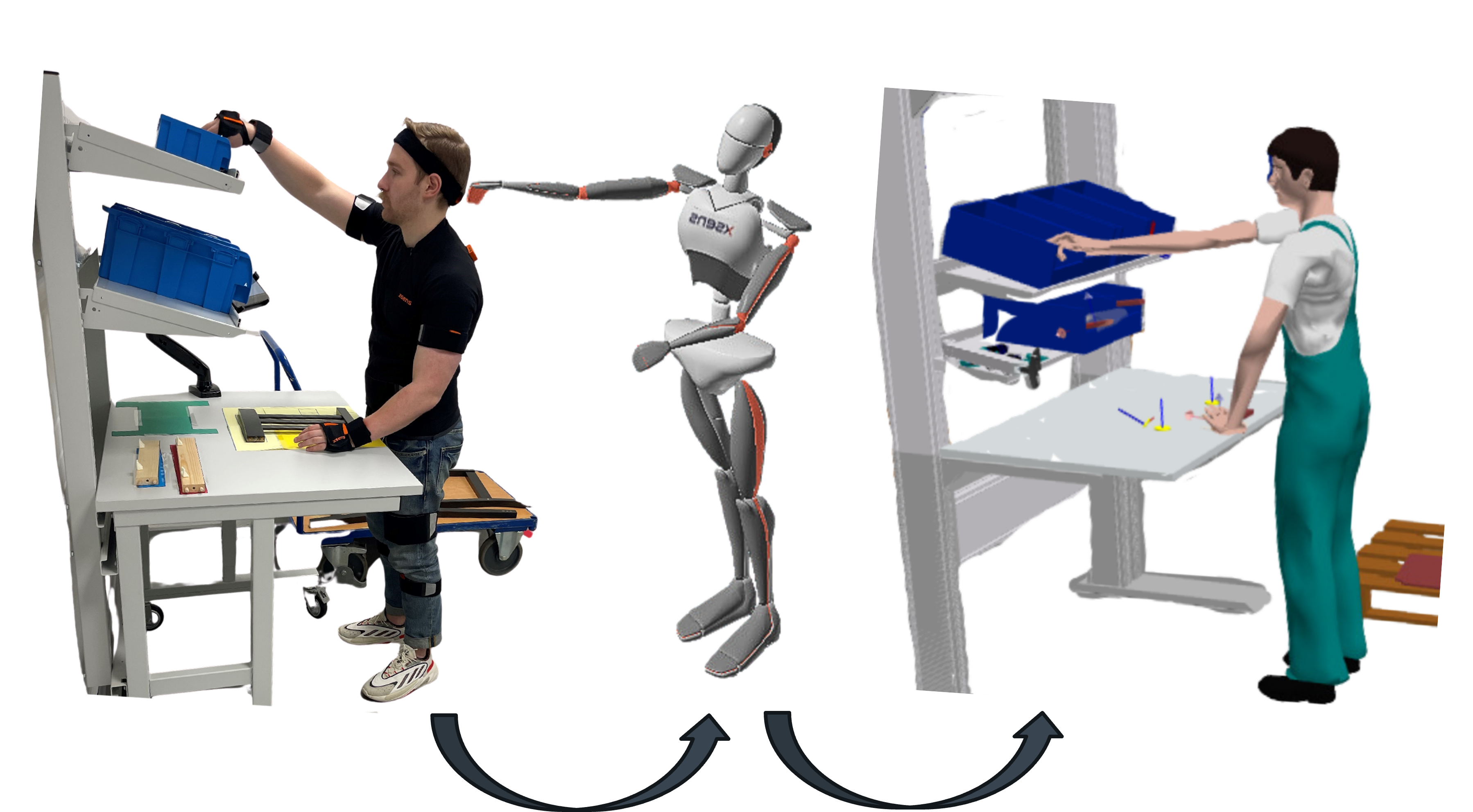

To optimize the simulation model, the real movements of the worker can be recorded using motion capturing and fed back into the model. Incorrect assumptions or inaccuracies in the planning can thus be actively reflected.

The Industry X.0 manual workstation at the WI-Modellfabrik serves as a technology carrier where new technologies can be tested and practical scenarios demonstrated. These scenarios show possible applications of technologies in and from practice, which are developed, evaluated and discussed by the students themselves. Scenarios developed so far are

New technologies form the basis for growth, employment and prosperity. They are fascinating for many people and their potential is overestimated (hype). On the other hand, technologies can also be misused or cause negative effects. It is therefore important to take a holistic view of technologies and to understand them within their technical and ethical limits.

A scenario has been created in which technologies that could influence the working environment of the future can be tested and experienced within their ethical boundaries. Two settings were initially created for this purpose:

The automation of processes is a central component of modern production strategies. It enables the efficient, low-error and consistent execution of recurring tasks - often around the clock.

The targeted use of machines, robotics and digital systems can reduce costs, increase quality and relieve employees of monotonous tasks. Automation therefore makes a decisive contribution to the productivity and competitiveness of companies.

Manual aircraft assembly is to be automated using collaborative robots and driverless transport systems. The individual parts are to be removed from a self-designed warehouse and transported to the assembly table of the UR5 using the UR3 and driverless transport system. The UR5 is used to assemble the aircraft. Assembly fixtures are required for automated assembly, which must also be designed.

Risk assessments are a key tool in occupational health and safety and are used to systematically identify and evaluate risks in the workplace. In production, they help to identify potential hazards at an early stage and define suitable protective measures. They therefore make an important contribution to the safety, health and motivation of employees and are required by law.

The integration of risk assessments into teaching is essential in order to provide students with a practical understanding of safety requirements and legal obligations in the production environment. Only those who are familiar with the significance and methodology can later assume responsibility and help shape safe working conditions.

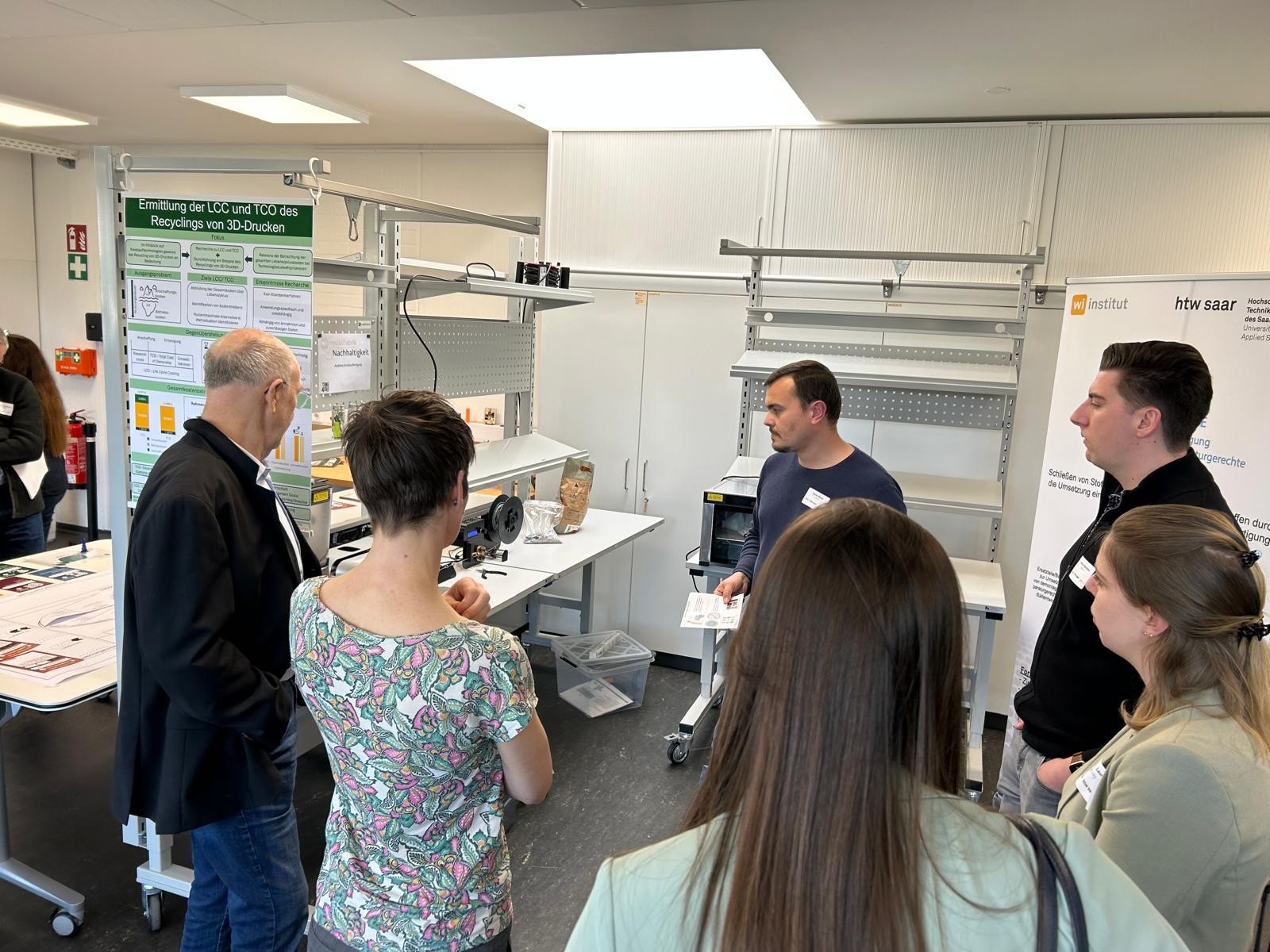

In the lecture, students first learn the legal principles (e.g. ArbSchG, BetrSichV) and the systematic approach to risk assessment. The students then analyze the Prusa MK4 8 3D printer located in the WI-Modellfabrik, identify sources of danger, develop protective measures and create operating instructions.

In times of increasing scarcity of raw materials and growing environmental requirements, automated disassembly is gaining strategic importance. It helps companies to meet legal requirements, increase recycling rates and combine ecological responsibility with economic efficiency.

The automated disassembly process is an innovative approach to the efficient and resource-saving dismantling of products, especially at the end of their life cycle. With the help of collaborative robotics, components are specifically recognized, detached and sorted - without manual intervention. This enables materials to be separated by type, reduces disposal costs and creates the basis for a sustainable circular economy.

In the WI model factory, automated disassembly is implemented using the UR5e and UR3e collaborative robots and the automated guided vehicle system (AGV). The AGV transports the "block" product to the workspace of the UR5e. The UR5e disassembles the block using custom-made devices and sorts the disassembled parts according to type and color.

With demographic change and an ageing workforce, the relevance of human-centered process design is increasing significantly. A forward-looking design, e.g. adapted reach spaces and working heights or supportive aids, not only protects the health of employees, but also maintains their performance and motivation in the long term.

Age-appropriate assembly planning is therefore an essential building block for sustainable productivity and social responsibility within the company. In the WI model factory, it is possible to record real assembly processes using technologies such as motion capturing and digital twins in combination with software for simulating work processes.

An age suit can be used to simulate a wide range of age-related movement and visual impairments. In combination with the motion capturing suit and the simulation program, assembly processes with various movement restrictions can be recorded, transferred to the simulation program, analysed, ergonomically evaluated and optimized.